1, Hydroxyl tus nqi: 1 gram polymer polyol muaj hydroxyl (-OH) tus nqi sib npaug rau cov milligrams ntawm KOH, chav tsev mgKOH / g.

2, Sib npaug: qhov nruab nrab molecular hnyav ntawm pab pawg ua haujlwm.

3, Isocyanate cov ntsiab lus: cov ntsiab lus ntawm isocyanate hauv cov molecule

4, Isocyanate Performance index: qhia txog qib ntawm isocyanate tshaj hauv cov mis polyurethane, feem ntau yog sawv cev los ntawm tsab ntawv R.

5. Chain extender: Nws yog hais txog cov dej cawv uas tsis tshua muaj molecular thiab amines uas tuaj yeem txuas ntxiv, nthuav tawm lossis tsim spatial network crosslinks ntawm cov saw hlau molecular.

6. Cov ntu nyuaj: Cov ntu ntu tau tsim los ntawm cov tshuaj tiv thaiv ntawm isocyanate, saw extender thiab crosslinker ntawm cov saw tseem ceeb ntawm polyurethane molecules, thiab cov pab pawg no muaj zog cohesion loj dua, qhov chaw ntim loj dua thiab ntau dua rigidity.

7, Mos ntu: carbon carbon ntsiab saw polymer polyol, yooj yooj yim yog zoo, nyob rau hauv lub polyurethane lub ntsiab saw rau lub saj zawg zog saw ntu.

8, Ib-kauj ruam txoj kev: yog hais txog oligomer polyol, diisocyanate, saw extender thiab catalyst tov tib lub sij hawm tom qab ncaj qha txhaj rau hauv pwm, ntawm ib tug tej yam kub curing molding txoj kev.

9, Prepolymer txoj kev: Thawj oligomer polyol thiab diisocyanate prepolymerization cov tshuaj tiv thaiv, los ua kom tiav NCO raws li polyurethane prepolymer, pouring thiab ces prepolymer cov tshuaj tiv thaiv nrog saw extender, kev npaj ntawm polyurethane elastomer txoj kev, hu ua prepolymer method.

10, Semi-prepolymer txoj kev: qhov sib txawv ntawm txoj kev semi-prepolymer thiab prepolymer txoj kev yog tias ib feem ntawm polyester polyol los yog polyether polyol yog ntxiv rau prepolymer nyob rau hauv daim ntawv ntawm ib tug sib tov nrog saw extender, catalyst, thiab lwm yam.

11, Kev txhaj tshuaj molding: Kuj hu ua Reaction Txhaj Molding RIM (Reaction Txhaj Moulding), nws yog ntsuas los ntawm oligomers nrog qhov hnyav molecular hauv cov kua, tam sim tov thiab txhaj rau hauv pwm tib lub sijhawm, thiab cov tshuaj tiv thaiv sai hauv cov pwm kab noj hniav, qhov hnyav molecular ntawm cov khoom nce sai heev. Ib txoj hauv kev los tsim cov polymers tshiab nrog cov txheej txheem tshiab ntawm pab pawg neeg ntawm kev kub ceev heev.

12, Foaming index: uas yog, tus naj npawb ntawm cov dej siv nyob rau hauv 100 feem ntawm polyether yog txhais raws li foaming index (IF).

13, Foaming cov tshuaj tiv thaiv: feem ntau yog hais txog cov tshuaj tiv thaiv dej thiab isocyanate los tsim cov urea hloov thiab tso CO2.

14, Gel cov tshuaj tiv thaiv: feem ntau yog hais txog kev tsim cov tshuaj tiv thaiv carbamate.

15, Gel lub sij hawm: nyob rau hauv tej yam kev mob, cov khoom ua kua los tsim gel yuav tsum tau lub sij hawm.

16, Milky lub sij hawm: thaum kawg ntawm cheeb tsam I, qhov tshwm sim milky tshwm nyob rau hauv cov kua theem polyurethane sib tov. Lub sij hawm no yog hu ua cream lub sij hawm nyob rau hauv tiam ntawm polyurethane ua npuas ncauj.

17, Chain expansion coefficient: yog hais txog qhov sib piv ntawm cov amino thiab hydroxyl pawg (unit: mo1) nyob rau hauv cov saw extender Cheebtsam (xws li cov saw txuas txuas ntxiv) rau cov nyiaj NCO hauv prepolymer, uas yog, tus lej mole (equivalent tooj) ratio of active hydrogen group to NCO.

18, Tsawg unsaturation polyether: feem ntau yog rau PTMG txoj kev loj hlob, PPG nqi, unsaturation txo mus rau 0.05mol / kg, ze rau qhov kev ua tau zoo ntawm PTMG, siv DMC catalyst, lub ntsiab ntau yam ntawm Bayer Acclaim series khoom.

19, Ammonia ester qib hnyav: kev tsim cov polyurethane hnyav los txiav txim siab lub zog tawg, volatilization tus nqi, tab sis kev tsim cov polyurethane siv hauv cov kuab tshuaj, yuav tsum tsom mus rau hauv tus account hnyav NC0 hauv polyurethane. Cov kuab tshuaj xws li cawv thiab ether cawv uas cuam tshuam nrog NCO pawg tsis tuaj yeem xaiv. Cov kuab tshuaj tsis tuaj yeem muaj cov impurities xws li dej thiab cawv, thiab tsis tuaj yeem muaj cov tshuaj alkali, uas yuav ua rau polyurethane deteriorate.

Cov kuab tshuaj ester tsis pub muaj dej, thiab yuav tsum tsis txhob muaj cov kua qaub dawb thiab cawv, uas yuav ua rau NCO pawg. Cov ester hnyav siv hauv polyurethane yuav tsum yog "ammonia ester qib hnyav" nrog purity siab. Uas yog, cov kuab tshuaj reacts nrog ntau tshaj isocyanate, thiab ces tus nqi ntawm unreacted isocyanate yog txiav txim nrog dibutylamine los ntsuam xyuas seb nws puas haum rau siv. Lub hauv paus ntsiab lus yog tias kev noj cov isocyanate tsis siv, vim nws qhia tau hais tias cov dej hauv ester, cawv, acid peb yuav haus tag nrho cov nqi ntawm isocyanate, yog tias tus naj npawb ntawm cov kuab tshuaj yuav tsum tau noj leqNCO pab pawg tau qhia, tus nqi yog zoo stability.

Isocyanate sib npaug tsawg dua 2500 tsis yog siv los ua cov kuab tshuaj polyurethane.

Lub polarity ntawm cov kuab tshuaj muaj kev cuam tshuam zoo rau cov tshuaj tiv thaiv ntawm resin tsim. Qhov ntau dua qhov polarity, qhov qeeb qeeb ntawm cov tshuaj tiv thaiv, xws li toluene thiab methyl ethyl ketone qhov sib txawv ntawm 24 lub sij hawm, qhov hnyav molecule polarity no loj, tuaj yeem tsim cov hydrogen daim ntawv cog lus nrog cov cawv hydroxyl pawg thiab ua rau cov tshuaj tiv thaiv qeeb.

Polychlorinated ester hnyav yog qhov zoo dua los xaiv cov kuab tshuaj tsw qab, lawv cov tshuaj tiv thaiv ceev nrawm dua li ester, ketone, xws li xylene. Kev siv cov ester thiab ketone cov kuab tshuaj tuaj yeem txuas ntxiv lub neej kev pab cuam ntawm ob ceg polyurethane thaum siv. Hauv kev tsim cov coatings, kev xaiv ntawm "ammonia-qib hnyav" tau hais ua ntej yog qhov zoo rau cov stabilizers khaws cia.

Ester cov kuab tshuaj muaj zog solubility, nruab nrab volatilization tus nqi, tsis tshua muaj toxicity thiab siv ntau dua, cyclohexanone kuj siv ntau dua, hydrocarbon cov kuab tshuaj muaj peev xwm dissolution tsawg, tsawg siv ib leeg, thiab ntau siv nrog lwm cov kuab tshuaj.

20, Lub tshuab tshuab lub cev: lub tshuab tshuab lub cev yog cov npuas dej uas tsim los ntawm kev hloov pauv ntawm lub cev ntawm cov khoom, uas yog, los ntawm kev nthuav dav ntawm cov pa roj compressed, volatilization ntawm cov kua lossis cov khoom tawg.

21, Tshuaj tshuab tshuab: tshuaj tshuab tshuab yog cov uas tuaj yeem tso cov pa roj xws li carbon dioxide thiab nitrogen tom qab cua sov decomposition, thiab tsim cov pores zoo nyob rau hauv cov polymer muaj pes tsawg leeg.

22, Lub cev crosslinking: muaj qee qhov nyuaj chains nyob rau hauv lub polymer mos saw, thiab cov saw tawv muaj tib lub cev muaj zog raws li cov roj hmab vulcanized tom qab tshuaj crosslinking ntawm qhov kub hauv qab lub softening point los yog melting point.

23, Chemical crosslinking: yog hais txog cov txheej txheem ntawm kev sib txuas cov saw loj molecular los ntawm cov khoom siv tshuaj lom neeg nyob rau hauv qhov kev txiav txim ntawm lub teeb, tshav kub, hluav taws xob hluav taws xob, hluav taws xob hluav taws xob, hluav taws xob hluav taws xob, ultrasound thiab crosslinking cov neeg ua haujlwm los tsim ib lub network lossis cov qauv polymer.

24, Foaming index: tus naj npawb ntawm cov dej sib npaug rau 100 feem ntawm polyether yog txhais ua foaming index (IF).

25. Hom isocyanates feem ntau siv los ntawm cov qauv?

A: Aliphatic: HDI, alicyclic: IPDI, HD, HMDI, Aromatic: TDI, MDI, PAPI, PPDI, NDI.

26. Hom isocyanates uas nquag siv? Sau tus qauv qauv

A: Toluene diisocyanate (TDI), diphenylmethane-4,4 '-diisocyanate (MDI), polyphenylmethane polyisocyanate (PAPI), liquefied MDI, hexamethylene-diisocyanate (HDI).

27. Lub ntsiab lus ntawm TDI-100 thiab TDI-80?

A: TDI-100 yog tsim los ntawm toluene diisocyanate nrog 2,4 qauv; TDI-80 yog hais txog kev sib tov uas muaj 80% toluene diisocyanate ntawm 2,4 qauv thiab 20% ntawm 2,6 qauv.

28. Dab tsi yog cov yam ntxwv ntawm TDI thiab MDI hauv kev sib xyaw ntawm cov khoom siv polyurethane?

A: Reactivity rau 2.4-TDI thiab 2.6-TDI. Lub reactivity ntawm 2,4-TDI yog ob peb zaug ntau dua li ntawm 2,6-TDI, vim hais tias 4-txoj hauj lwm NCO nyob rau hauv 2,4-TDI nyob deb ntawm 2-txoj hauj lwm NCO thiab methyl pawg, thiab muaj yuav luag. tsis muaj steric tsis kam, thaum NCO ntawm 2,6-TDI cuam tshuam los ntawm cov nyhuv steric ntawm ortho-methyl pawg.

Ob pawg NCO ntawm MDI nyob deb sib nrug thiab tsis muaj cov neeg hloov pauv nyob ib puag ncig, yog li cov haujlwm ntawm ob NCO yog qhov loj heev. Txawm hais tias ib tus NCO koom nrog cov tshuaj tiv thaiv, cov haujlwm ntawm NCO tseem poob qis, thiab cov haujlwm tseem tseem loj heev. Yog li ntawd, lub reactivity ntawm MDI polyurethane prepolymer yog loj dua li ntawm TDI prepolymer.

29.HDI, IPDI, MDI, TDI, NDI qhov twg yellowing kuj zoo dua?

A: HDI (tshwj tsis yog cov xim daj aliphatic diisocyanate), IPDI (ua los ntawm polyurethane resin nrog kev ruaj ntseg zoo thiab tshuaj lom neeg, feem ntau yog siv los tsim cov qib siab tsis muaj xim polyurethane resin).

30. Lub hom phiaj ntawm kev hloov kho MDI thiab kev hloov kho ntau yam

A: Liquefied MDI: Hloov lub hom phiaj: liquefied ntshiab MDI yog liquefied hloov MDI, uas overcomes ib co tsis xws luag ntawm ntshiab MDI (khoom nyob rau hauv chav tsev kub, melting thaum siv, ntau cua sov cuam tshuam rau kev ua tau zoo), thiab kuj muab lub hauv paus rau ntau yam ntawm kev hloov kho rau kev txhim kho thiab txhim kho kev ua haujlwm ntawm MDI-based polyurethane cov ntaub ntawv.

Txoj kev:

① urethane hloov liquefied MDI.

② carbodiimide thiab uretonimine hloov MDI liquefied.

31. Hom polyols feem ntau siv li cas?

A: Polyester polyol, polyether polyol

32. Muaj pes tsawg txoj kev tsim khoom muaj rau polyester polyols?

A: Nqus melting txoj kev B, carrier gas melting txoj kev C, azeotropic distillation method

33. Dab tsi yog cov qauv tshwj xeeb ntawm cov pob txha molecular ntawm polyester thiab polyether polyols?

A: Polyester polyol: Ib qho macromolecular cawv compound uas muaj ester pawg ntawm cov pob txha molecular thiab ib pawg hydroxyl (-OH) ntawm pawg kawg. Polyether polyols: Polymers los yog oligomers uas muaj ether bonds (-O-) thiab kawg bands (-Oh) los yog amine pawg (-NH2) nyob rau hauv lub caj qaum qauv ntawm lub molecule.

34. Dab tsi yog hom polyether polyols raws li lawv cov yam ntxwv?

A: Muaj zog polyether polyols, grafted polyether polyols, nplaim retardant polyether polyols, heterocyclic hloov polyether polyols, polytetrahydrofuran polyols.

35. Muaj pes tsawg hom polyethers zoo ib yam raws li tus neeg sawv cev pib?

A: Polyoxide propylene glycol, polyoxide propylene triol, tawv npuas polyether polyol, tsis tshua muaj unsaturation polyether polyol.

36. Qhov txawv ntawm hydroxy-terminated polyethers thiab amine-terminated polyethers yog dab tsi?

Aminoterminated polyethers yog polyoxide allyl ethers uas cov hydroxyl kawg yog hloov los ntawm ib pawg amine.

37. Hom polyurethane catalysts feem ntau siv? Qhov twg siv ntau yam suav nrog?

A: Tertiary amine catalysts, feem ntau siv ntau yam yog: triethylenediamine, dimethylethanolamine, n-methylmorpholine, N, n-dimethylcyclohexamine

Metallic alkyl compounds, feem ntau siv ntau yam yog: organotin catalysts, tuaj yeem muab faib ua stannous octoate, stannous oleate, dibutyltin dilaurate.

38. Dab tsi yog cov feem ntau siv polyurethane saw extenders lossis crosslinkers?

A: Polyols (1, 4-butanediol), alicyclic alcohols, aromatic alcohols, diamines, cawv amines (ethanolamine, diethanolamine)

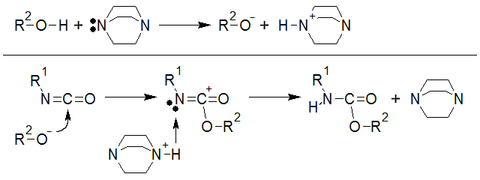

39. Cov tshuaj tiv thaiv mechanism ntawm isocyanates

A: Cov tshuaj tiv thaiv ntawm isocyanates nrog cov tshuaj nquag hydrogen yog tshwm sim los ntawm qhov chaw nucleophilic ntawm cov nquag hydrogen compound molecule tawm tsam NCO raws carbon atom. Cov tshuaj tiv thaiv mechanism yog raws li nram no:

40. Cov qauv ntawm isocyanate cuam tshuam li cas rau cov reactivity ntawm NCO pawg?

A: Cov electronegativity ntawm pawg AR: yog tias pawg R yog ib pawg electron absorbing, electron huab ntom ntom ntawm C atom hauv pawg -NCO yog qis dua, thiab nws yog qhov yooj yim rau kev tawm tsam ntawm nucleophiles, uas yog, nws Nws yog qhov yooj yim dua los ua cov tshuaj tiv thaiv nucleophilic nrog cawv, amines thiab lwm yam sib xyaw. Yog hais tias R yog ib pab pawg neeg pub khoom siv hluav taws xob thiab raug xa mus los ntawm huab cua hluav taws xob, lub tshuab hluav taws xob huab cua ceev ntawm C atom hauv pawg -NCO yuav nce, ua rau nws tsis tshua muaj kev cuam tshuam rau kev tawm tsam ntawm nucleophiles, thiab nws lub peev xwm tshuaj tiv thaiv nrog cov hydrogen compounds. txo. B. Induction effect: Vim hais tias cov aromatic diisocyanate muaj ob pawg NCO, thaum thawj -NCO noob koom nrog cov tshuaj tiv thaiv, vim yog cov nyhuv conjugated ntawm lub nplhaib aromatic, pawg -NCO uas tsis koom nrog cov tshuaj tiv thaiv yuav ua lub luag haujlwm. ntawm electron absorbing pab pawg, yog li ntawd cov tshuaj tiv thaiv kev ua ntawm thawj NCO pab pawg yog txhim kho, uas yog induction nyhuv. C. steric nyhuv: Hauv cov tshuaj tsw qab diisocyanate molecules, yog tias ob pawg -NCO nyob rau hauv ib lub nplhaib uas muaj ntxhiab tib lub sijhawm, ces qhov cuam tshuam ntawm ib pawg NCO ntawm cov reactivity ntawm lwm pab pawg NCO feem ntau tseem ceeb dua. Txawm li cas los xij, thaum ob pawg NCO nyob hauv cov nplhaib sib txawv hauv tib lub molecule, los yog lawv tau sib cais los ntawm hydrocarbon chains los yog aromatic rings, kev sib cuam tshuam ntawm lawv yog me me, thiab nws txo qis nrog qhov nce ntawm qhov ntev ntawm cov saw hydrocarbon los yog cov khoom siv hluav taws xob. nce tus naj npawb ntawm cov nplhaib aromatic.

41. Hom active hydrogen compounds thiab NCO reactivity

A: Aliphatic NH2> Aromatic pawg Bozui OH> Dej> Secondary OH> Phenol OH> Carboxyl pawg> Hloov urea> Amido> Carbamate. (Yog hais tias cov huab cua electron ceev ntawm qhov chaw nucleophilic siab dua, electronegativity muaj zog dua, thiab cov tshuaj tiv thaiv kev ua haujlwm nrog isocyanate siab dua thiab cov tshuaj tiv thaiv ceev nrawm dua; Txwv tsis pub, kev ua haujlwm tsawg.)

42. Kev cuam tshuam ntawm hydroxyl compounds ntawm lawv cov reactivity nrog isocyanates

A: Lub reactivity ntawm active hydrogen tebchaw (ROH los yog RNH2) muaj feem xyuam rau cov khoom ntawm R, thaum R yog ib tug electron rho tawm pawg (tsawg electronegativity), nws yog ib qho nyuaj rau hloov hydrogen atoms, thiab cov tshuaj tiv thaiv ntawm active hydrogen tebchaw thiab NCO nyuaj dua; Yog tias R yog ib qho khoom siv hluav taws xob pub dawb, qhov rov ua haujlwm ntawm cov khoom siv hydrogen nrog NCO tuaj yeem txhim kho.

43. Kev siv cov tshuaj isocyanate nrog dej yog dab tsi

A: Nws yog ib qho ntawm cov tshuaj tiv thaiv hauv kev npaj ntawm polyurethane ua npuas ncauj. Cov tshuaj tiv thaiv ntawm lawv thawj zaug ua rau tsis ruaj tsis khov carbamic acid, uas tom qab ntawd tawg mus rau hauv CO2 thiab amines, thiab yog tias cov isocyanate ntau dhau, qhov tshwm sim amine reacts nrog cov isocyanate los tsim urea.

44. Nyob rau hauv kev npaj ntawm polyurethane elastomers, cov dej ntsiab lus ntawm polymer polyols yuav tsum nruj me ntsis tswj.

A: Tsis muaj npuas yuav tsum tau nyob rau hauv elastomers, coatings thiab fibers, yog li cov dej ntsiab lus nyob rau hauv raw cov ntaub ntawv yuav tsum nruj me ntsis tswj, feem ntau tsawg tshaj li 0.05%.

45. Qhov sib txawv ntawm cov teebmeem catalytic ntawm amine thiab tin catalysts ntawm cov tshuaj tiv thaiv isocyanate

A: Tertiary amine catalysts muaj siab catalytic efficiency rau cov tshuaj tiv thaiv ntawm isocyanate nrog dej, thaum tin catalysts muaj siab catalytic efficiency rau cov tshuaj tiv thaiv ntawm isocyanate nrog hydroxyl pawg.

46. Vim li cas polyurethane resin tuaj yeem suav tias yog cov khoom thaiv polymer, thiab cov qauv ntawm cov saw hlau yog dab tsi?

Teb: Vim hais tias cov saw ntu ntawm polyurethane resin yog tsim los ntawm cov ntu tawv thiab mos, ntu tawv yog hais txog cov saw ntu tsim los ntawm cov tshuaj tiv thaiv ntawm isocyanate, saw extender thiab crosslinker ntawm cov saw tseem ceeb ntawm polyurethane molecules, thiab cov pab pawg no muaj kev sib koom ua ke loj dua. lub zog, loj qhov chaw ntim thiab ntau dua rigidity. Cov ntu muag yog hais txog cov pa roj carbon-carbon lub ntsiab saw polymer polyol, uas muaj qhov hloov tau zoo thiab yog qhov hloov tau yooj yim hauv cov saw hlau polyurethane.

47. Dab tsi yog yam uas cuam tshuam rau cov khoom ntawm cov ntaub ntawv polyurethane?

A: Pab pawg cohesion zog, hydrogen daim ntawv cog lus, crystallinity, crosslinking degree, molecular hnyav, ntu nyuaj, ntu mos.

48. Cov khoom siv dab tsi yog qhov muag muag thiab tawv ntawm cov saw tseem ceeb ntawm cov ntaub ntawv polyurethane

A: Cov ntu mos yog tsim los ntawm oligomer polyols (polyester, polyether diols, thiab lwm yam), thiab ntu nyuaj yog tsim los ntawm polyisocyanates lossis lawv ua ke nrog cov saw hlau me me.

49. Cov ntu mos thiab cov ntu nyuaj cuam tshuam li cas ntawm cov khoom ntawm polyurethane?

A: Mos ntu: (1) Qhov hnyav molecular ntawm cov mos mos: piv txwv tias qhov hnyav molecular ntawm polyurethane yog tib yam, yog tias cov ntu mos yog polyester, lub zog ntawm polyurethane yuav nce ntxiv nrog qhov nce ntawm qhov hnyav ntawm molecular. polyester diol; Yog tias qhov muag muag yog polyether, lub zog ntawm polyurethane txo qis nrog qhov nce ntawm qhov hnyav molecular ntawm polyether diol, tab sis qhov elongation nce. (2) Lub crystallinity ntawm cov mos mos ntu: Nws muaj kev txhawb nqa ntau dua rau crystallinity ntawm linear polyurethane saw ntu. Feem ntau, crystallization yog qhov zoo rau kev txhim kho kev ua haujlwm ntawm cov khoom siv polyurethane, tab sis qee zaum crystallization txo qis qhov kub thiab txias ntawm cov khoom, thiab cov crystalline polymer feem ntau opaque.

Nyuaj ntu: Cov saw hlau ntu feem ntau cuam tshuam rau qhov muag muag thiab melting kub thiab kub siab ntawm cov khoom polymer. Polyurethanes npaj los ntawm cov tshuaj tsw qab isocyanates muaj cov nplhaib uas muaj ntxhiab tsw, yog li lub zog ntawm lub zog ntawm cov ntu nyuaj nce, thiab cov khoom siv zog feem ntau loj dua li ntawm aliphatic isocyanate polyurethanes, tab sis kev tiv thaiv rau ultraviolet degradation yog pluag, thiab nws yooj yim rau yellowing. Aliphatic polyurethanes tsis daj.

50. Polyurethane ua npuas ncauj cais

A: (1) ua npuas ncauj thiab mos ua npuas ncauj, (2) siab ceev thiab tsis tshua muaj npuas npuas, (3) polyester hom, polyether hom ua npuas ncauj, (4) TDI hom, MDI hom ua npuas ncauj, (5) polyurethane ua npuas ncauj thiab polyisocyanurate ua npuas ncauj, (6) ib-kauj ruam txoj kev thiab prepolymerization txoj kev ntau lawm, nruam txoj kev thiab intermittent ntau lawm, (8) thaiv npuas thiab molded ua npuas ncauj.

51. Tej yam tshwm sim hauv kev npaj ua npuas ncauj

A: Nws yog hais txog cov tshuaj tiv thaiv ntawm -NCO nrog -OH, -NH2 thiab H2O, thiab thaum reacting nrog polyols, "gel cov tshuaj tiv thaiv" hauv cov txheej txheem foaming feem ntau yog hais txog kev tsim cov tshuaj tiv thaiv carbamate. Vim tias cov khoom siv ua npuas ncauj siv cov khoom siv ntau yam khoom siv raw, ib qho kev sib txuas sib txuas tau txais, uas tso cai rau lub foaming system kom gel sai sai.

Cov tshuaj tiv thaiv foaming tshwm sim nyob rau hauv lub foaming system nrog muaj dej. Lub npe hu ua "foaming reaction" feem ntau yog hais txog cov tshuaj tiv thaiv dej thiab isocyanate los tsim cov urea hloov pauv thiab tso CO2.

52. Nucleation mechanism ntawm npuas

Cov khoom siv raw reacts nyob rau hauv cov kua los yog nyob ntawm qhov kub thiab txias uas ua los ntawm cov tshuaj tiv thaiv los tsim cov khoom gaseous thiab volatilize cov roj. Nrog rau kev nce qib ntawm cov tshuaj tiv thaiv thiab kev tsim cov tshuaj tiv thaiv kub ntau, cov tshuaj gaseous thiab volatilization nce ntxiv. Thaum cov roj concentration nce siab tshaj qhov saturation concentration, cov npuas uas muaj kev ruaj ntseg pib tsim nyob rau hauv cov tshuaj theem thiab nce.

53. Lub luag haujlwm ntawm foam stabilizer hauv kev npaj ntawm polyurethane ua npuas ncauj

A: Nws muaj cov nyhuv emulsification, kom cov kev sib nrig sib solubility ntawm cov khoom ntawm cov khoom ua npuas ncauj yog txhim khu kev qha; Tom qab qhov sib ntxiv ntawm silicone surfactant, vim tias nws txo qis qhov nro γ ntawm cov kua, lub zog dawb ntxiv uas yuav tsum tau muaj rau cov roj dispersion yog txo, yog li ntawd cov huab cua dispersed nyob rau hauv cov ntaub ntawv raw yog ntau dua nucleate thaum lub sij hawm sib tov, uas. txhawb kev tsim cov npuas me me thiab txhim kho kev ruaj ntseg ntawm cov npuas dej.

54. Stability mechanism ntawm ua npuas ncauj

A: Qhov sib ntxiv ntawm cov surfactants tsim nyog yog qhov tsim nyog rau kev tsim cov npuas zoo dispersion.

55. Tsim mechanism ntawm qhib cell ua npuas ncauj thiab kaw cell ua npuas ncauj

A: Kev tsim cov txheej txheem ntawm qhib-hlwb ua npuas ncauj: Feem ntau, thaum muaj lub siab loj hauv npuas, lub zog ntawm cov npuas phab ntsa tsim los ntawm cov tshuaj tiv thaiv gel tsis siab, thiab cov yeeb yaj kiab phab ntsa tsis tuaj yeem tiv taus qhov ncab. los ntawm cov pa nce siab, cov npuas phab ntsa zaj duab xis yog rub, thiab cov roj khiav tawm ntawm qhov tawg, ua rau cov npuas qhib qhib.

Kaw-cell ua npuas ncauj tsim mechanism: Rau cov txheej txheem ua npuas tawv, vim yog cov tshuaj tiv thaiv ntawm polyether polyols nrog ntau lub luag haujlwm thiab qhov hnyav molecular nrog polyisocyanate, gel ceev yog ceev ceev, thiab cov pa roj hauv cov npuas tsis tuaj yeem rhuav tshem cov npuas phab ntsa. , yog li tsim lub kaw-cell ua npuas ncauj.

56. Foaming mechanism ntawm lub cev foaming tus neeg saib xyuas thiab tshuaj foaming tus neeg saib xyuas

A: Lub tshuab tshuab lub cev: Tus neeg saib xyuas lub cev yog cov npuas pores tau tsim los ntawm kev hloov pauv ntawm lub cev ntawm ib yam khoom, uas yog, los ntawm kev nthuav dav ntawm cov pa roj compressed, volatilization ntawm cov kua lossis cov khoom tawg.

Tshuaj tshuab tshuab: Tshuaj tshuab tshuab yog cov tebchaw uas, thaum decomposed los ntawm tshav kub, tso gases xws li carbon dioxide thiab nitrogen thiab tsim zoo pores nyob rau hauv lub polymer muaj pes tsawg leeg.

57. Txoj kev npaj ntawm mos polyurethane ua npuas ncauj

A: Ib-kauj ruam txoj kev thiab prepolymer txoj kev

Prepolymer txoj kev: uas yog, cov polyether polyol thiab ntau tshaj TDI cov tshuaj tiv thaiv yog tsim rau hauv ib lub prepolymer uas muaj dawb NCO pab pawg, thiab ces tov nrog dej, catalyst, stabilizer, thiab lwm yam., ua npuas ncauj. Ib-kauj ruam txoj kev: Ntau yam ntawm cov khoom siv raw yog ncaj qha mus rau hauv lub taub hau sib xyaw los ntawm kev suav, thiab ib kauj ruam yog ua los ntawm cov npuas dej, uas tuaj yeem muab faib ua ntu ntu thiab ntu.

58. Cov yam ntxwv ntawm kab rov tav foaming thiab ntsug foaming

Txoj kev sib npaug ntawm cov phaj siab: tus cwj pwm los ntawm kev siv cov ntawv saum toj kawg nkaus thiab cov phaj npog sab saum toj. Overflow groove txoj kev: tus cwj pwm los ntawm kev siv cov hlais zawj thiab conveyor siv tsaws phaj.

Vertical foaming yam ntxwv: koj tuaj yeem siv qhov me me kom tau txais thaj tsam loj ntawm qhov ua npuas ncauj, thiab feem ntau yog siv lub tshuab ua npuas dej kom tau txais tib seem ntawm qhov thaiv, qhov ntws theem yog 3 mus rau 5 npaug loj dua qhov ntsug. foaming; Vim hais tias ntawm qhov loj hla ntawm lub npuas thaiv, tsis muaj daim tawv nqaij sab sauv thiab qis, thiab cov npoo ntawm daim tawv nqaij kuj yog nyias, yog li qhov kev txiav yog txo qis heev. Cov khoom siv npog thaj tsam me me, qhov siab ntawm cov nroj tsuag yog li 12 ~ 13m, thiab cov nqi peev ntawm cov nroj tsuag thiab cov khoom siv qis dua li cov txheej txheem kab rov tav foaming; Nws yog ib qho yooj yim los hloov lub hopper thiab cov qauv los tsim cylindrical los yog cov duab plaub lub cev ua npuas ncauj, tshwj xeeb tshaj yog round ua npuas ncauj billets rau rotary txiav.

59. Cov ntsiab lus tseem ceeb ntawm kev xaiv raw khoom rau kev npaj ua npuas ncauj mos

A: Polyol: polyether polyol rau zoo tib yam thaiv npuas, molecular hnyav yog feem ntau 3000 ~ 4000, feem ntau polyether triol. Polyether triol nrog qhov hnyav molecular ntawm 4500 ~ 6000 yog siv rau kev ua npuas dej siab. Nrog rau qhov nce ntawm qhov hnyav molecular, lub zog tensile, elongation thiab resilience ntawm npuas nce. Lub reactivity ntawm zoo sib xws polyethers txo. Nrog rau kev nce qib ntawm kev ua haujlwm ntawm polyether, cov tshuaj tiv thaiv tau nrawm dua, qhov sib txawv ntawm qhov sib txuas ntawm polyurethane yog nce, ua npuas ncauj hardness yog nce, thiab elongation yog txo. Isocyanate: Cov khoom siv raw ntawm isocyanate ntawm polyurethane soft block ua npuas ncauj yog toluene diisocyanate (TDI-80). Cov kev ua haujlwm qis ntawm TDI-65 tsuas yog siv rau polyester polyurethane ua npuas ncauj lossis tshwj xeeb polyether ua npuas ncauj. Catalyst: Cov txiaj ntsig catalytic ntawm bulk soft foaming tuaj yeem muab faib ua ob pawg: ib qho yog organometallic compounds, stannous caprylate yog feem ntau siv; Lwm hom yog tertiary amines, feem ntau siv los ua dimethylaminoethyl ethers. Ua npuas ncauj stabilizer: Hauv polyester polyurethane bulk ua npuas ncauj, uas tsis yog-silicon surfactants feem ntau yog siv, thiab nyob rau hauv polyether bulk ua npuas ncauj, organosilica-oxidized olefin copolymer yog tsuas yog siv. Foaming tus neeg saib xyuas: Feem ntau, tsuas yog dej yog siv los ua foaming tus neeg saib xyuas thaum qhov ntom ntawm polyurethane soft block npuas yog ntau tshaj 21 kg ib cubic meter; Cov ntsiab lus kub kub tsawg xws li methylene chloride (MC) yog siv los ua cov tshuaj tua kab mob nkaus xwb hauv cov qauv uas tsis tshua muaj.

60. Kev cuam tshuam ntawm ib puag ncig tej yam kev mob ntawm lub cev muaj zog ntawm block foams

A: Cov nyhuv ntawm qhov kub thiab txias: cov tshuaj tiv thaiv foaming ntawm polyurethane nrawm thaum cov khoom kub nce, uas yuav ua rau muaj kev pheej hmoo ntawm kev kub nyhiab thiab hluav taws kub hauv cov qauv tsim. Kev cuam tshuam ntawm huab cua humidity: Nrog rau qhov nce ntawm cov av noo, vim yog cov tshuaj tiv thaiv ntawm cov pab pawg isocyanate hauv cov npuas dej nrog cov dej hauv cov huab cua, qhov tawv ntawm cov npuas dej txo qis thiab elongation nce. Lub zog tensile ntawm cov npuas dej nce nrog kev nce ntawm pawg urea. Cov nyhuv ntawm atmospheric siab: Rau tib lub mis, thaum foaming ntawm qhov siab dua, qhov ceev yog txo qis.

61. Qhov sib txawv tseem ceeb ntawm cov khoom siv raw khoom siv rau txias molded mos ua npuas ncauj thiab kub molded ua npuas ncauj

A: Cov khoom siv raw khoom siv hauv kev kho txias molding muaj qhov ua haujlwm siab, thiab tsis tas yuav muaj cua sov sab nraud thaum kho, cia siab rau cov cua sov tsim los ntawm lub cev, cov tshuaj tiv thaiv tuaj yeem ua tiav hauv lub sijhawm luv, thiab pwm tuaj yeem raug tso tawm hauv ob peb feeb tom qab txhaj tshuaj ntawm cov khoom siv raw. Cov khoom siv raw reactivity ntawm kub curing molding ua npuas ncauj yog tsawg, thiab cov tshuaj tiv thaiv sib tov yuav tsum tau rhuab ua ke nrog cov pwm tom qab foaming nyob rau hauv pwm, thiab cov khoom ua npuas ncauj yuav raug tso tawm tom qab nws yog tag nrho matured nyob rau hauv lub ci channel.

62. Yuav ua li cas yog cov yam ntxwv ntawm txias-moulded mos ua npuas ncauj piv nrog kub-molded ua npuas ncauj

A: ① Cov txheej txheem tsim khoom tsis tas yuav tsum muaj cua sov sab nraud, tuaj yeem txuag tau ntau qhov cua sov; ② High sag coefficient (collapsibility ratio), kev nplij siab zoo; ③ Siab rebound tus nqi; ④ Ua npuas ncauj tsis muaj nplaim taws kuj muaj qee yam nplaim hluav taws kub; ⑤ Lub voj voog luv luv, tuaj yeem txuag pwm, txuag nqi.

63. Cov yam ntxwv thiab kev siv ntawm cov npuas mos thiab tawv npuas feem

A: Cov yam ntxwv ntawm cov npuas mos: Cov qauv ntawm tes ntawm polyurethane mos npuas feem ntau yog qhib. Feem ntau, nws muaj qhov tsis tshua muaj zog, zoo rov qab zoo, kev nqus cov suab, huab cua permeability, txuag hluav taws xob thiab lwm yam khoom. Kev Siv: Feem ntau yog siv rau cov rooj tog zaum, cov khoom siv hauv ncoo, cov khoom siv hauv lub rooj zaum hauv tsheb, ntau yam ntaub ntawv mos padding laminated composite cov ntaub ntawv, industrial thiab civil soft foam kuj yog siv los ua cov ntaub ntawv lim, suab rwb thaiv tsev cov ntaub ntawv, cov ntaub ntawv poob siab, cov ntaub ntawv zoo nkauj, cov ntaub ntawv ntim thiab cov khoom siv thermal rwb thaiv tsev.

Cov yam ntxwv ntawm cov ua npuas ncauj nruj: polyurethane ua npuas ncauj muaj lub teeb yuag, muaj zog tshwj xeeb thiab zoo qhov ntev; Lub thermal rwb thaiv tsev kev ua tau zoo ntawm polyurethane rigid ua npuas ncauj yog superior. Lub zog nplaum nplaum; Kev laus kev ua haujlwm zoo, kev pabcuam ntev adiabatic; Cov tshuaj tiv thaiv sib tov muaj fluidity zoo thiab tuaj yeem sau cov kab noj hniav los yog qhov chaw ntawm cov duab zoo meej. Cov khoom siv raw ntawm polyurethane nyuaj ua npuas ncauj ntau lawm muaj qhov ua haujlwm siab, tuaj yeem ua tiav sai sai, thiab tuaj yeem ua tiav kev ua haujlwm siab thiab ntau lawm hauv lub Hoobkas.

Kev Siv: Siv los ua cov khoom siv rwb thaiv tsev rau cov tub yees, lub tub yees, lub tub yees, cov thawv txias, cov kav dej txias thiab cov kav dej kub rwb thaiv tsev, lub tsev phab ntsa thiab ru tsev rwb thaiv tsev, rwb thaiv tsev sandwich board, thiab lwm yam.

64. Cov ntsiab lus tseem ceeb ntawm cov txheej txheem nyuaj npuas tsim

A: Polyols: polyether polyols siv rau cov ntaub ntawv nyuaj ua npuas ncauj feem ntau muaj zog, siab hydroxyl tus nqi (tsawg molecular hnyav) polypropylene oxide polyols; Isocyanate: Tam sim no, cov isocyanate siv rau cov npuas tawv yog tsuas yog polymethylene polyphenyl polyisocyanate (feem ntau hu ua PAPI), uas yog, crude MDI thiab polymerized MDI; Tshuab tshuab: (1) CFC tshuab tshuab (2) HCFC thiab HFC tshuab tshuab (3) pentane tshuab (4) dej; Ua npuas ncauj stabilizer: Cov npuas dej stabilizer siv rau polyurethane rigid foam formulation feem ntau yog ib qho thaiv polymer ntawm polydimethylsiloxane thiab polyoxolefin. Tam sim no, feem ntau ua npuas ncauj stabilizers feem ntau yog Si-C hom; Catalyst: Lub catalyst ntawm cov npuas nyuaj formulation yog tsuas yog tertiary amine, thiab organotin catalyst yuav siv tau nyob rau hauv tshwj xeeb zaus; Lwm yam additives: Raws li cov kev xav tau thiab kev xav tau ntawm kev siv sib txawv ntawm cov khoom siv polyurethane rigid ua npuas ncauj, nplaim retardants, qhib cov neeg ua hauj lwm, cov pa luam yeeb inhibitors, anti-aging agents, anti-mildew agents, toughening agents thiab lwm yam additives yuav muab ntxiv rau lub mis.

65. Tag nrho cov tawv nqaij molding ua npuas ncauj npaj txoj cai

A: ib qho ntawm daim tawv nqaij ua npuas ncauj (ISF), tseem hu ua self skinning foam (self skinning foam), yog ib qho ua npuas ncauj yas uas ua rau nws cov tawv nqaij tawv thaum lub sijhawm tsim khoom.

66. Cov yam ntxwv thiab kev siv ntawm polyurethane microporous elastomers

A: Cov yam ntxwv: polyurethane elastomer yog ib qho thaiv polymer, feem ntau tsim los ntawm oligomer polyol saj zawg zog ntev saw mos ntu, diisocyanate thiab saw extender los ua ib ntu nyuaj, ntu nyuaj thiab ntu ntu sib txuas, ua kom rov ua dua cov txheej txheem. Ntxiv rau qhov muaj cov ammonia ester pawg, polyurethane tuaj yeem tsim hydrogen bonds hauv thiab nruab nrab ntawm cov molecules, thiab cov ntu mos thiab tawv tuaj yeem tsim cov cheeb tsam microphase thiab tsim microphase sib cais.

67. Cov yam ntxwv tseem ceeb ntawm polyurethane elastomers yog dab tsi

A: Cov yam ntxwv ntawm kev ua tau zoo: 1, siab zog thiab elasticity, tuaj yeem ua tau ntau yam ntawm hardness (Shaw A10 ~ Shaw D75) kom muaj lub siab elasticity; Feem ntau, qhov yuav tsum tau qis hardness tuaj yeem ua tiav yam tsis muaj plasticizer, yog li tsis muaj teeb meem tshwm sim los ntawm plasticizer tsiv teb tsaws; 2, nyob rau hauv tib lub hardness, muaj peev xwm nqa tau ntau dua li lwm cov elastomers; 3, hnav tsis kam, nws hnav tsis kam yog 2 mus rau 10 npaug ntawm cov roj hmab ntuj; 4. Cov roj thiab tshuaj lom neeg ua haujlwm zoo heev; Aromatic polyurethane hluav taws xob tiv taus; Zoo heev oxygen kuj thiab ozone kuj; 5, kev ua haujlwm siab, kev qaug zog zoo thiab kev poob siab, haum rau kev siv ntau zaus; 6, tsis tshua muaj kub hloov tau zoo; 7, zoo tib yam polyurethane tsis tuaj yeem siv siab tshaj 100 ℃, tab sis kev siv cov mis tshwj xeeb tuaj yeem tiv taus 140 ℃ siab; 8, molding thiab ua cov nqi kuj tsawg.

68. Polyurethane elastomers raug cais raws li polyols, isocyanates, kev tsim khoom, thiab lwm yam

A: 1. Raws li cov khoom siv raw ntawm oligomer polyol, polyurethane elastomers tuaj yeem muab faib ua hom polyester, polyether hom, polyolefin hom, polycarbonate hom, thiab lwm yam. Polyether hom tuaj yeem muab faib ua polytetrahydrofuran hom thiab polypropylene oxide hom raws li hom tshwj xeeb; 2. Raws li qhov sib txawv ntawm diisocyanate, nws tuaj yeem muab faib ua aliphatic thiab aromatic elastomers, thiab subdivided rau hauv TDI hom, MDI hom, IPDI hom, NDI hom thiab lwm yam; Los ntawm cov txheej txheem tsim, polyurethane elastomers ib txwm muab faib ua peb pawg: hom casting (CPU), thermoplasticity (TPU) thiab hom sib xyaw (MPU).

69. Dab tsi yog qhov cuam tshuam rau cov khoom ntawm polyurethane elastomers los ntawm kev pom ntawm cov qauv molecular?

A: Los ntawm qhov pom ntawm cov qauv molecular, polyurethane elastomer yog ib qho thaiv polymer, feem ntau yog tsim los ntawm oligomer polyols saj zawg zog ntev saw mos ntu, diisocyanate thiab saw extender los tsim ib ntu nyuaj, ntu nyuaj thiab ntu ntu sib txuas, ua kom rov ua dua. chav tsev qauv. Ntxiv rau qhov muaj cov ammonia ester pawg, polyurethane tuaj yeem tsim hydrogen bonds hauv thiab nruab nrab ntawm cov molecules, thiab cov ntu mos thiab tawv tuaj yeem tsim cov cheeb tsam microphase thiab tsim microphase sib cais. Cov yam ntxwv ntawm cov qauv no ua rau polyurethane elastomers muaj kev hnav zoo heev thiab tawv, hu ua "cov roj hmab hnav-resistant".

70. Kev ua tau zoo sib txawv ntawm hom polyester zoo tib yam thiab polytetrahydrofuran ether hom elastomers

A: Polyester molecules muaj ntau pawg polar ester (-COO-), uas tuaj yeem tsim muaj zog intramolecular hydrogen bonds, yog li polyester polyurethane muaj lub zog siab, hnav tsis kam thiab roj tsis kam.

Lub elastomer npaj los ntawm polyether polyols muaj kev ruaj ntseg hydrolysis zoo, huab cua tsis kam, tsis tshua muaj kub yooj thiab pwm kuj. Cov ntawv xov xwm / Polymer kev tshawb fawb

Post lub sij hawm: Jan-17-2024